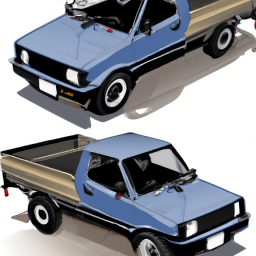

Replacing the transmission torque sensor on a Datsun Truck 320 involves several steps, including gathering the necessary tools and components, removing the old sensor, and installing the new one. click here for more details on the download manual…..

- #WILLITRUN RARE 1965 DATSUN 320 PICK UP TRUCK Let’s go! #Datsun #minituck WELCOME BACK to Clint’s FIGURE IT OUT GARAGE! This week we pick up a super rare 1965 Datsun 320 pickup truck!

- Datsun 510 Wagon 1967 he Datsun 510 was a series of the Datsun Bluebird sold from 1968 to 1973, and offered outside the U.S. and Canada as the …

Below is a detailed guide to help you through the process:

### Tools and Materials Needed:

1. **Tools:**

– Socket set (including metric sockets)

– Wrench set

– Screwdrivers (flathead and Phillips)

– Torque wrench

– Pliers

– Jack and jack stands (if needed)

– Safety goggles and gloves

2. **Replacement Parts:**

– New transmission torque sensor compatible with the Datsun Truck 320

– New gaskets or O-rings (if applicable)

– Electrical connector (if damaged)

### Step-by-Step Replacement Procedure:

#### Step 1: Preparation

– **Safety First:** Ensure you’re wearing safety goggles and gloves. Park the vehicle on a flat surface, engage the parking brake, and disconnect the negative battery terminal to avoid electrical shorts.

– **Lift the Vehicle (if necessary):** If you need more room to work under the truck, use a jack to lift it and secure it with jack stands.

#### Step 2: Locate the Torque Sensor

– The transmission torque sensor is typically located on the transmission itself, near the output shaft or where the transmission connects to the driveshaft. Consult the vehicle’s service manual for the exact location if needed.

#### Step 3: Remove the Old Torque Sensor

1. **Disconnect Electrical Connectors:**

– Carefully disconnect the electrical connector Attached to the torque sensor. If the connector is stubborn, use pliers to gently pull it apart.

2. **Remove Mounting Bolts:**

– Using the appropriate socket, remove the bolts securing the torque sensor to the transmission. Keep these bolts as you will need them for the new sensor installation.

3. **Remove the Sensor:**

– Once the bolts are removed, gently pull the torque sensor off the transmission. Be mindful of any O-rings or gaskets that may come off with it. If they are damaged, you will need to replace them.

#### Step 4: Install the New Torque Sensor

1. **Prepare the New Sensor:**

– If the new sensor comes with an O-ring or gasket, apply a small amount of oil or grease to it for a better seal. This helps prevent leaks and makes installation easier.

2. **Position the New Sensor:**

– Align the new torque sensor with the mounting hole on the transmission. Ensure it is positioned correctly and that any alignment pins or guides fit into place.

3. **Secure the Sensor:**

– Insert the mounting bolts and tighten them using a torque wrench to the manufacturer’s specified torque settings (consult the service manual for the correct torque specifications).

4. **Reconnect Electrical Connectors:**

– Reconnect the electrical connector to the new torque sensor. Ensure it clicks into place securely.

#### Step 5: Reassembly and Testing

and Testing

– **Reconnect the Battery:** Reconnect the negative battery terminal and ensure it is secure.

– **Lower the Vehicle (if lifted):** If you lifted the vehicle, carefully lower it back to the ground.

#### Step 6: Test the New Sensor

– Start the engine and allow it to idle for a few minutes. Check for any warning lights on the dashboard Related to the transmission.

– Take the vehicle for a short test drive to ensure that the torque sensor is functioning correctly and that there are no unusual noises or issues.

### Conclusion

Replacing the transmission torque sensor on a Datsun Truck 320 can be accomplished with basic mechanical skills and the right tools. Always refer to the vehicle’s service manual for specific details Related to your model. If you encounter any issues or are unsure at any step, it may be wise to consult a professional mechanic for assistance.

A boost controller is an essential component in turbocharged and supercharged engines, designed to manage the amount of boost pressure generated by the forced induction system. Its primary function is to regulate the air pressure entering the engine, which directly affects power output and engine performance. By controlling the boost levels, a boost controller enables drivers to optimize engine performance for various driving conditions, enhancing both efficiency and power.

There are two main types of boost controllers: manual and electronic. Manual boost controllers typically consist of a simple mechanical device that allows the driver to adjust the wastegate’s spring pressure, thereby controlling the boost level. This type is often favored by enthusiasts for its simplicity and direct control. On the other hand, electronic boost controllers utilize sensors and computer algorithms to dynamically adjust boost levels based on real-time engine performance data. these systems can provide more precise control, enabling features such as boost mapping for different driving modes, which can improve both drivability and performance.

Boost controllers also play a crucial role in preventing engine knock and ensuring that the engine operates within safe parameters. By managing boost levels effectively, they help maintain optimal air-fuel ratios, reduce exhaust temperatures, and improve overall engine longevity. In performance applications, properly tuned boost controllers can significantly enhance acceleration and throttle response, making them a popular modification among automotive enthusiasts Looking to maximize their vehicle’s performance.